Mining Career Field Structure

The basic elements found in the earth’s crust combine in strange and beautiful ways to create many different types of minerals. The variety of raw materials is as diverse as the uses for them. At least 1,400 minerals of inorganic origin are known, approximately 300 of which have become useful to industry.

The basic elements found in the earth’s crust combine in strange and beautiful ways to create many different types of minerals. The variety of raw materials is as diverse as the uses for them. At least 1,400 minerals of inorganic origin are known, approximately 300 of which have become useful to industry.

Basically, the output of the mining industry may be classified into three groups: energy minerals, nonmetallic minerals, and metallic minerals. Typical energy minerals are the fossil fuels, such as coal and uranium. Typical nonmetallic minerals include phosphate rock, used in fertilizers; limestone rock, used in cement, lime, and iron production; salt, used domestically and in industry for the production of basic chemicals; and sand and gravel, used extensively in construction. Typical metallic minerals are iron ores, copper ores, and bauxite, which is the raw material for the aluminum industry. The most heavily mined minerals are coal, iron, nonferrous metals, and construction materials, such as gravel.

The easily accessible deposits that provided mineral supplies in the past are gone. The remaining available minerals lie beneath the earth’s surface. The development of special tools, techniques, instruments, and methods of interpretation help locate new mineral sources. Essentially, this aspect of mining requires an understanding of the earth’s chemistry and physics, as well as some type of intuition about the earth and its ore deposits.

What resources to mine, when to start mining, how to finance operations, and where to market and at what price are questions confronting the mineral economist. Since ore bodies are unevenly distributed throughout the world, a system has developed for distributing the output of ore bodies to those who need them. This system is motivated fundamentally by the law of supply and demand.

In addition, local townships, counties, states, nations, and international bodies desire to influence the workings of the fundamental law of supply and demand for minerals so that their own welfare can be maximized. The influences of these organizations on the policies of a mining firm must be thoroughly understood if the firm is to survive and prosper.

Discovering viable places to mine is a science that requires trained and experienced professionals to determine whether or not ore deposits and mineralized masses are technically, economically, socially, and politically minable. Scientists, engineers, and technicians are brought together as a team, usually with a specific kind of mineral target in mind.

Geologists, geophysicists, and geochemists need a fundamental understanding of the ways ore bodies developed on Earth to discover more readily where ore bodies are likely to be found. Initial efforts to locate likely mine sites often start with satellite photographs. This is followed by aerial photographs and geophysical sensing, which in turn are followed by more intense and detailed study of the targeted area. Sometimes the discovery is underwater, such as the deep-sea nodules, or in the polar regions or even under existing towns.

Once a mineralized mass is found, a valuation engineer confirms the discovery and authorizes the removal of the ore. The valuation function requires a wide range of talents, from an understanding of ore deposit geology to knowing the fundamentals of marketing mineral products.

To address such practical matters as cost and profitability, valuation engineers must gather and analyze geological, geophysical, and geochemical data. To be profitable, the prospective ore body must be obtainable through efficient extraction by available or developing technology and equipment.

The valuation engineer must also consider social and political policy. Societal values change with time and the needs of people. Political parties and governments also change. A mining enterprise must respond to these changes and anticipate future trends and laws.

Should valuation engineers deem an area worth mining, their decision launches an ever-widening circle of design and construction activity. Some mining projects today are so large that a joint venture of several companies, or a partnership between government and private industry, is created to carry them out.

The design sector of mining links the research and development phases with actual construction. Once management has stated its objectives in a given mineral project, design engineers proceed to accomplish the objectives. Mining, industrial, and mineral engineers together must make a working system that safely meets the output requirements with a minimum expenditure of staff and equipment.

For underground mining, design engineers plan detailed drilling procedures and determine the number and location of shafts, slopes (diagonally dug shafts), and main extraction openings. Surface structures and roads usually are designed by civil engineers. In many cases, railroads are required. Engineers determine the size, number, kind, and layout of the various pieces of equipment. Electrical engineers and mechanical engineers are responsible for designing various controls and for organizing the distribution of power and other services throughout the mine.

For large-scale mining in remote areas, more often than not a town site with its services and facilities must be designed and constructed. This requires the further services of architects, water supply engineers, and sanitation engineers.

The design engineers hand over a set of plans and specifications to the construction engineers, who are responsible for translating the plans into the reality of steel and concrete, head frames and mills, and shafts and tunnels. The actual construction may be handled by contractors or engineering concerns that specialize in heavy construction. Whether this is the case or not, the usual procedure is to determine a plan for construction, the quantities of material and other items needed, and the estimated cost of each construction operation.

Fieldwork starts with a survey team sent to the site to lay out the mine and its facilities. Construction of access roads and auxiliary buildings begins immediately, and the team assesses any work already done on essential services such as electricity and water. Progress reports are submitted by the fieldworkers, and plans are changed accordingly.

For underground mining, construction entails sinking shafts and developing main extraction openings, underground workshops, and other openings important to mine operation. A choice must be made between conventional drill-and-blast methods and shaft-and-tunnel boring with machines. The use of shaft-and-tunnel boring machines is the newer method, but it must be carefully chosen to cope with the variety of geological conditions encountered.

Boring machines require substantial capital investment and hence must be operated and maintained with skill and care. Teamwork among engineers, mechanics, and operating personnel is needed for effective and efficient operation. Essentially, these machines bore a 20- foot-diameter or larger tunnel or shaft by thrusting an array of cutting bits against the rock face. As the machine’s cutting head rotates, the bits chip and break off the rock in front of them. Large hydraulic jacks bear against the side of the bored opening and provide restraint against the machine’s thrust.

Boring operations run continuously, stopping only for bit changes and repairs. Tunnel advances of a hundred feet or more per 24 hours can be accomplished in relatively soft rock. Since the machine is boring blind, lasers are used to ensure that deviation from the underground target is minimal. When boring operations are completed, the shaft is equipped with the necessary supports and facilities.

Open pit mines are developed when the ore body is close to the surface of the ground. Typically, the pit is developed in a series of levels called benches. Haul roads are constructed between benches so that material can be moved from any location in the pit to various receiving points. Alternative haulage from the pit may be performed by conveyors or railroad trains. The receiving point may be an ore mill, leaching dump, waste dump, or ore storage pile. Giant trucks with capacities up to 240 tons move about on this network of roads and are carefully scheduled so that no loading operation or receiving point is empty. Large drills, bulldozers, and power shovels work to ensure a continuous flow of ore out of the pit. In this way, open pit mining can move more than 600,000 tons of ore and rock in a 24-hour period.

The nature of the mineral deposit determines how open pit mining methods are employed. Placer mining methods are used for the exploitation of platinum, tin, diamond, and gold deposits. In Florida, phosphates are mined by surface methods. Large quantities of earth are mined and processed to recover small quantities of these substances.

The treatment of mining wastewater and the handling and safe disposal of other mining wastes are large problems. There is often a great deal of opposition to mining projects because of their adverse effects on the environment, including air, water, and noise pollution, as well as destruction of land and animal habitats. Strip mining of coal may be done in mountainous regions as well as in the lowlands. Although the methods are fundamentally the same, the geometry of the resulting pit is different and gives rise to a host of different problems. One concern is land reclamation, which is more of a problem for coal producers than for hard rock mining companies.

Low equipment and labor costs make open pit mining the cheapest and most economical method for producing low-grade or low-value material. Rock- and earth-moving equipment works on a scale that is hard to believe. Power shovels and draglines capable of moving 100 tons at a time are common. High output rates mean that the scale of trucks, bulldozers, and other equipment must be large.

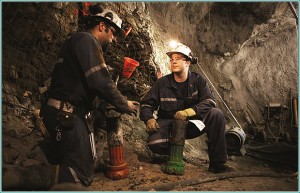

Operating personnel take over when construction is completed. The pace of work increases, for performance in meeting production goals is the criterion by which everything is measured. Teamwork and cooperation are essential. Drillers, blasters, loading machine operators, haulage operators, supply workers, and safety personnel work in a cycle of operations that meet production goals at the lowest possible costs.

The operations department also provides opportunities for mining engineers, metallurgists, mineral economists, industrial engineers, and chemical engineers. These professionals establish process controls and performance standards, evaluate jobs, train employees, and review cost control plans.

Maintenance of plant and equipment is sufficiently important to justify a separate department, since the dollar investment in both plant and equipment may be thousands of dollars per worker. The actual maintenance is in the hands of skilled craftsworkers and technicians such as mechanics, machinists, drafters, electricians, and instrument technicians, who are trained and equipped to overhaul all major plant facilities. All maintenance and operating work requires keeping complete and accurate records concerning equipment durability and efficiency. The analysis of these records also yields the information needed for inventory and stock requirements.

Shift bosses, or mine captains, play key management roles in the mining industry. They transform the desires of upper management into action. The shift boss’s responsibilities may be summarized as meeting the required daily output while considering the health and safety of the workers.

The shift boss must continually make personal inspections, regularly examining the fans and ventilation apparatus of an underground mine, looking at the condition of the shaft and main extraction openings and examining the electrical system. In any type of mine, the shift boss must talk with the workers, formulate independent opinions of conditions, and report to the company managers. The shift boss may also meet with local labor representatives and negotiate solutions to any problems or concerns.

Mine managers keep informed through reports from the mine shift bosses, their assistants, and personal inspections and investigations. Mine managers and shift bosses differ in their responsibilities. The shift boss may have to decide: Should we replace the float valve at pump station 1? Should we send people from production operations to the maintenance crew? The mine manager and the people at the top management levels, on the other hand, might be thinking: Should we mine more actively in mine No. 2 than in No. 3? Is it possible to bring out a new mining venture without unduly disturbing the existing marketing structure? The choice among alternative plans that are broad in scope is management’s responsibility.

The sales force in the mining industry is responsible for cultivating buyers of their product and keeping in contact with them. Most mineral commodities are sold according to specifications. Industrial users need certain qualities in their raw materials and require suppliers to meet those specifications. Salespeople are vitally important because they personally represent the company to the buyer. Knowing the wishes of buyers, they can apprise the company of the shifting demand for mineral products.

Salespeople in the mining industry must be familiar with the workings of the commodity markets and the flow of minerals in national and international commerce. Because they are required to compete in both price and specifications, they must know their company’s abilities and products intimately. They must know how various mineral commodities may interchange in the industry.