Packaging engineers design, develop, and specify containers for all types of goods, such as food, clothing, medicine, housewares, toys, electronics, appliances, and computers. In creating these containers, some of the packaging engineer’s activities include product and cost analysis, management of packaging personnel, development and operation of packaging filling lines, and negotiations with customers or sales representatives.

Packaging engineers may also select, design, and develop the machinery used for packaging operations. They may either modify existing machinery or design new machinery to be used for packaging operations.

Packaging Engineer Career History

Certain packages, particularly glass containers, have been used for more than 3,000 years; the metal can was developed to provide food for Napoleon’s army. However, the growth of the packaging industry developed during the industrial revolution, when shipping and storage containers were needed for the increased numbers of goods produced. As the shipping distance from producer to consumer grew, more care had to be given to packaging so goods would not be damaged in transit. Also, storage and safety factors became important with the longer shelf life required for goods produced.

Modern packaging methods have developed since the 1920s with the introduction of cellophane wrappings. Since World War II, early packaging materials such as cloth and wood have been largely replaced by less expensive and more durable materials such as steel, aluminum, and plastics such as polystyrene. Modern production methods have also allowed for the low-cost, mass production of traditional materials such as glass and paperboard. Government agencies, manufacturers, and designers are constantly trying to improve packaging so that it is more convenient, safe, and informative.

Modern packaging methods have developed since the 1920s with the introduction of cellophane wrappings. Since World War II, early packaging materials such as cloth and wood have been largely replaced by less expensive and more durable materials such as steel, aluminum, and plastics such as polystyrene. Modern production methods have also allowed for the low-cost, mass production of traditional materials such as glass and paperboard. Government agencies, manufacturers, and designers are constantly trying to improve packaging so that it is more convenient, safe, and informative.

Today, packaging engineers must also consider environmental factors when designing packaging because the disposal of used packages has presented a serious problem for many communities. The United States uses more than 500 billion packages yearly; 50 percent of these are used for food and beverages and another 40 percent for other consumer goods. To help solve this problem, packaging engineers attempt to come up with solutions such as the use of recyclable, biodegradable, or less bulky packaging.

Packaging Engineer Job Description

Packaging engineers plan, design, develop, and produce containers for all types of products. When developing a package, they must first determine the purpose of the packaging and the needs of the end users and their clients. Packaging for a product may be needed for a variety of reasons: for shipping, storage, display, or protection. A package for display must be attractive as well as durable and easy to store; labeling and perishability are important considerations, especially for food, medicine, and cosmetics. If the packaging purpose is for storage and shipping, then ease of handling and durability have to be considered. Safety factors are involved if the materials to be packaged are hazardous, such as toxic chemicals or explosives. Finally, the costs of producing and implementing the packaging have to be considered, as well as the packaging material’s impact on the environment.

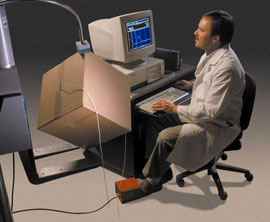

After determining the purpose of the packaging, the engineers study the physical properties and handling requirements of the product in order to develop the best kind of packaging. They study drawings and descriptions of the product or the actual product itself to learn about its size, shape, weight, and color, the materials used, and the way it functions. They decide what kind of packaging material to use and with the help of designers and production workers, they make sketches, draw up plans, and make samples of the package. These samples, along with lists of materials and cost estimates, are submitted to management or directly to the customer. Computer design programs and other related software may be used in the packaging design and manufacturing process.

When finalizing plans for packaging a product, packaging engineers contribute additional expertise in other areas. They are concerned with efficient use of raw materials and production facilities as well as conservation of energy and reduction of costs. For instance, they may use materials that can be recycled, or they may try to cut down on weight and size. They must keep up with the latest developments in packaging methods and materials and often recommend innovative ways to package products. Once all the details for packaging are worked out, packaging engineers may be involved in supervising the filling and packing operations, operating production lines, or drawing up contracts with customers or sales representatives. They should be knowledgeable about production and manufacturing processes, as well as sales and customer service.

After a packaging sample is approved, packaging engineers may supervise the testing of the package. This may involve simulation of all the various conditions a packaged good may be subjected to, such as temperature, handling, and shipping.

This can be a complex operation involving several steps. For instance, perishable items such as food and beverages have to be packaged to avoid spoilage. Electronic components have to be packaged to prevent damage to parts. Whether the items to be packaged are food, chemicals, medicine, electronics, or factory parts, considerable knowledge of the properties of these products is often necessary to make suitable packaging.

Design and marketing factors also need to be considered when creating the actual package that will be seen by the consumer. Packaging engineers work with graphic designers and packaging designers to design effective packaging that will appeal to consumers. For this task, knowledge of marketing, design, and advertising are essential. Packaging designers consider color, shape, and convenience as well as labeling and other informative features when designing packages for display. Very often, the consumer is able to evaluate a product only from its package.

The many different kinds of packages require different kinds of machinery and skills. For example, the beverage industry produces billions of cans, bottles, and cardboard containers. Often packaging engineers are involved in selecting and designing packaging machinery along with other engineers and production personnel. Packaging can be manufactured either at the same facility where the goods are produced or at facilities that specialize in producing packaging materials.

The packaging engineer must also consider safety, health, and legal factors when designing and producing packaging. Various guidelines apply to the packaging process of certain products and the packaging engineer must be aware of these regulations. Labeling and packaging of products are regulated by various federal agencies such as the Federal Trade Commission and the Food and Drug Administration. For example, the Consumer Product Safety Commission requires that safe packaging materials be used for food and cosmetics.

Packaging Engineer Career Requirements

High School

During high school, you should take classes that will prepare you for a college engineering education. Concentrate on mathematics, including algebra, geometry, trigonometry, and calculus, as well as sciences, including physics and chemistry. You will also benefit from taking computer science, mechanical drawing, economics, and accounting classes. English, art, computer-aided design, and graphic arts classes are also recommended.

Postsecondary Training

Several colleges and universities offer a major in packaging engineering. These programs may be offered through an engineering school or a school of packaging within a university. Both bachelor of science and master of science degrees are available. It generally takes four or five years to earn a bachelor’s degree and two additional years to earn a master’s degree. A master’s degree is not required to be a packaging engineer, although many professionals pursue advanced degrees, particularly if they plan to specialize in a specific area or do research. Many students take their first job in packaging once they have earned a bachelor’s degree, while other students earn a master’s degree immediately upon completing their undergraduate studies.

Students interested in this field often structure their own programs. In college, if no major is offered in packaging engineering, students can choose a related discipline, such as mechanical, industrial, electrical, chemical, materials, or systems engineering. It is useful to take courses in graphic design, computer science, marketing, and management.

Students enrolled in a packaging engineering program usually take the following courses during their first two years: algebra, trigonometry, calculus, chemistry, physics, accounting, economics, finance, and communications. During the remaining years, classes focus on core packaging subjects, such as packaging materials, package development, packaging line machinery, and product protection and distribution. Elective classes include topics concentrating on packaging and the environment, packaging laws and regulation, and technical classes on specific materials. Graduate studies, or those classes necessary to earn a master’s degree, include advanced classes in design, analysis, and materials and packaging processes.

Certification or Licensing

The Institute of Packaging Professionals, a professional society, offers two levels of certification: certified professional in training (CPIT) and certified packaging professional (CPP). The CPIT is available to college students, recent graduates, and professionals who have less than six years of experience in the field. Requirements for this certification include passing a multiple-choice test and an essay test. The CPP can be earned by those with at least six years of experience in the field. In addition to the experience requirement, candidates must fulfill two other qualifications from the following: Present a resume of activities, write a professional paper or hold a patent, pass a multiple choice test, and pass an essay test. Although certification is not required, many professional engineers obtain it to show that they have mastered specified requirements and have reached a certain level of expertise.

For those interested in working with the specialized field of military packaging technology, the School of Military Packaging Technology offers a program resulting in certification as a military packaging professional. This program is cosponsored by the National Institute of Packaging, Handling, and Logistics Engineers. Generally, a person earns a bachelor of science degree in packaging engineering before taking these specialized courses.

Special licensing is required for engineers whose work affects the safety of the public. Much of the work of packaging engineers, however, does not require a license even though their work affects such factors as food and drug spoilage, protection from hazardous materials, and protection from damage. Licensing laws vary from state to state, but, in general, states have similar requirements. They require that an engineer must be a graduate of an approved engineering school, have four years of engineering experience, and pass the state licensing examination. A state board of engineering examiners administers the licensing and registration of engineers.

Other Requirements

Packaging engineers should have the ability to solve problems and think analytically and creatively. They must work well with people, both as a leader and as a team player. They should also be able to write and speak well in order to deal effectively with other workers and customers, and in order to document procedures and policies. In addition, a packaging engineer should have the ability to manage projects and people.

Exploring Packaging Engineer Career

To get firsthand experience in the packaging industry, you can call local manufacturers to see how they handle and package their products. Often, factories will allow visitors to tour their manufacturing and packaging facilities.

Another way to learn about packaging is by observing the packaging that you encounter every day, such as containers for food, beverages, cosmetics, and household goods. Visit stores to see how products are packaged, stored, or displayed. Notice the shape and labeling on the container, its ease of use, durability for storage, convenience of opening and closing, disposability, and attractiveness.

You may also explore your aptitude and interest in a packaging career through graphic design courses, art classes that include construction activities, and computer-aided design classes. Participating in hobbies that include designing and constructing objects from different types of materials can also be beneficial. You can also learn about the industry by reading trade publications or visiting their Web sites, such as Packaging World (http://www.packworld.com/) and Packaging Digest (http://www.packagingdigest.com/).

Employers

Packaging engineers are employed by almost every manufacturing industry. Pharmaceutical, beverage, cosmetics, and food industries are major employers of packaging engineers. Some packaging engineers are hired to design and develop packaging while others oversee the actual production of the packages. Some companies have their own packaging facilities while other companies subcontract the packaging to specialized packing firms. Manufacturing and packaging companies can be large, multinational enterprises that manufacture, package, and distribute numerous products, or they can be small operations that are limited to the production of one or two specific products. Specialized packaging companies hire employees for all aspects of the packaging design and production process. Worldwide manufacturing offers career opportunities around the world. The federal government and the armed services also have employment opportunities for packaging engineers.

Starting Out

College graduates with a degree in packaging or a related field of engineering should find it easy to get jobs as the packaging industry continues its rapid growth. Many companies send recruiters to college campuses to meet with graduating students and interview them for positions with their companies. Students can also learn about employment possibilities through their schools’ placement services, job fairs, classified advertisements in newspapers and trade publications, and referrals from teachers. Students who have participated in an internship or work-study program through a college may learn about employment opportunities through contacts with industry professionals.

Students can also research companies they are interested in working for and apply directly to the person in charge of packaging or the personnel office.

Advancement

Beginning packaging engineers generally do routine work under the supervision of experienced engineers and may also receive some formal training through their company. As they become more experienced, they are given more difficult tasks and more independence in solving problems, developing designs, or making decisions.

Some companies provide structured programs in which packaging engineers advance through a sequence of positions to more advanced packaging engineering positions. For example, an entry-level engineer might start out by producing engineering layouts to assist product designers, advance to the position of product designer, and ultimately move into a management position.

Packaging engineers may advance from being a member of a team to a project supervisor or department manager. Qualified packaging engineers may advance through their department to become a manager or vice president of their company. To advance to a management position, the packaging engineer must demonstrate good technical and production skills and managerial ability. After years of experience, a packaging engineer might wish to become self-employed as a packaging consultant.

To improve chances for advancement, the packaging engineer may wish to get a master’s degree in another branch of engineering or in business administration. Many executives in government and industry began their careers as engineers. Some engineers become patent attorneys by combining a law degree with their technical and scientific knowledge.

Many companies encourage continuing education throughout one’s career and provide training opportunities in the form of in-house seminars and outside workshops. Taking advantage of any training offered helps one to develop new skills and learn technical information that can increase chances for advancement. Many companies also encourage their employees to participate in professional association activities. Membership and involvement in professional associations are valuable ways to stay current on new trends within the industry, to familiarize oneself with what other companies are doing, and to make contacts with other professionals in the industry. Many times, professionals learn about opportunities for advancement in new areas or at different companies through the contacts they have made at association events.

Earnings

Salaries for packaging engineers vary based on factors such as the industry in which they work (food and beverage, pharmaceuticals, cosmetics, personal care, etc.), the size of the employer, the area of the country in which they live, and their years of professional experience. A survey by Salary.com found the average entry-level salary for a packaging engineer in 2006 was $50,951 per year. The mid-level salary was $57,506, with senior-level packaging engineers easily earning $85,030 to $96,523 or more as they gain experience and advance within a company.

A survey conducted by Packworld.com found that the annual median salary, including bonus, of engineers was $70,200 in 2005. The average respondent reported earning $75,259. Corporate managers earned the highest average compensation, including salary and bonus, of $104,000.

Benefits vary from company to company but can include any of the following: medical, dental, and life insurance; paid vacations, holidays, and sick days; profit sharing; 401(k) plans; bonus and retirement plans; and educational assistance programs. Some employers pay fees and expenses for participation in professional associations.

Work Environment

The working conditions for packaging engineers vary with the employer and with the tasks of the engineer. Those who work for companies that make packaging materials or who direct packaging operations might work around noisy machinery. Generally, they have offices near the packaging operations where they consult with others in their department, such as packaging machinery technicians and other engineers.

Packaging engineers also work with nontechnical staff such as designers, artists, and marketing and financial people. Packaging engineers must be alert to keeping up with new trends in marketing and technological developments.

Most packaging engineers have a five-day, 40-hour workweek, although overtime is not unusual. In some companies, particularly during research and design stages, product development, and the start up of new methods or equipment, packaging engineers may work 10-hour days or longer and work on weekends.

Some travel may be involved, especially if the packaging engineer is also involved in sales. Also, travel between plants may be necessary to coordinate packaging operations. At various stages of developing packaging, the packaging engineer will probably be engaged in hands-on activities. These activities involve handling objects, working with machinery, carrying light loads, and using a variety of tools, machines, and instruments.

The work of packaging engineers also involves other, social concerns such as consumer protection, environmental pollution, and conservation of natural resources. Packaging engineers are constantly searching for safer, tamper-proof packaging, especially because harmful substances have been found in some food, cosmetics, and drugs. They also experiment with new packaging materials and utilize techniques to conserve resources and reduce the disposal problem. Many environmentalists are concerned with managing the waste from discarded packages. Efforts are being made to stop littering; to recycle bottles, cans, and other containers; and to use more biodegradable substances in packaging materials. The qualified packaging engineer, then, will have a broad awareness of social issues.

Packaging Engineer Career Outlook

The packaging industry, which employs more than a million people, offers almost unlimited opportunities for packaging engineers. Packaging engineers work in almost any industry because virtually all manufactured products need one or more kinds of packaging. Some of the industries with the fastest growing packaging needs are food, drugs, and cosmetics.

The demand for packaging engineers is expected to be strong as newer, faster ways of packaging are continually being sought to meet the needs of economic growth, world trade expansion, and the environment. Increased efforts are also being made to develop packaging that is easy to open for the growing aging population and those persons with disabilities.